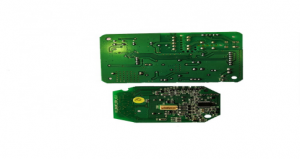

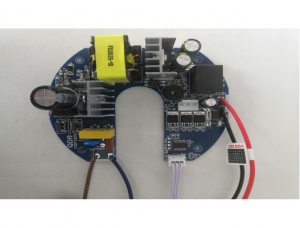

36W PCB With Sensor Ceiling Fan Board

Quick Details:

Type:Rigid PCB

Base Material: FR4 TG140

Copper Thickness:1OZ/2OZ

Board Thickness:1mm

Min. Hole Size:0.01mm

Min. Line Width:0.02mm

Min. Line Spacing:0.01mm

Surface Finishing:HASL

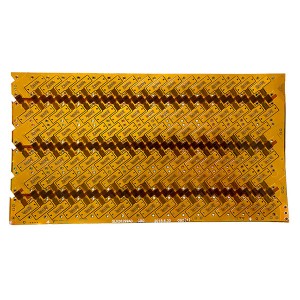

Board Size:Customized

Working temperature:-5℃-60℃

Number of layers:Double Layers

Storage temperature:-20℃-80℃

Rated working voltage:AC100V-250V

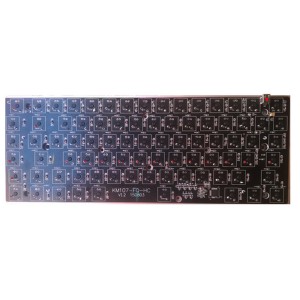

Solder mask color:Black.Red.Yellow.White.Blue.Green

PCB Standard:IPC-A-610 E

SMT Efficiency:BGA.QFP.SOP.QFN.PLCC.CHIP

PCB Assembly Test:Visual Inspection (default), AOI, FCT, X-RAY

Substrates Material:Aluminum, 22F,CEM-1,CEM-3,FR4

Breakdown voltage:2.0-2.4KV(AC)

Product Description

Cooperation mode:

1. Schematic design: circuit schematic can be designed according to customer’s requirements.

2, PCB design: PCB diagram can be designed according to the schematic from customer. PCB and bill of materials can be analyzed on the basis of customer’s samples.

3, Software design: SCM software development and design, can be written according to customer’s requirements, with the needed function. Or rewrite some part of software to fit customer’s actual hardware.

Mode of production cooperation:

1. The written program, schematic, PCB data and bill of materials can be sent to customer for the processing of program and circuit boards.

2, We can design the program for customer, help to produce circuit boards according to customer’s requirements. Multi-style cooperation to meet different customer’s needs.

3, Development and design, low charge. only cost and development fees are required, which can be returned after a certain amount of orders. Can be developed and designed on basis of customer’s program requirements.

PCB PROCESSING CAPABILITY :

|

1 |

Layers | Single Sided,2 to 18 Layer |

| 2 | Board material type | FR4,CEM-1,CEM-3,ceramic substrate board,aluminum based board, High-TG, Rogers and more |

| 3 | Compound material lamination | 4 to 6 layers |

| 4 | Maximum dimension | 610 x 1,100mm |

| 5 | Dimension tolerance | ±0.13mm |

| 6 | Board thickness coverage | 0.2 to 6.00mm |

| 7 | Board thickness tolerance | ±10% |

| 8 | DK thickness | 0.076 to 6.00mm |

| 9 | Minimum line width | 0.10mm |

| 10 | Minimum line space | 0.10mm |

| 11 | Outer layer copper thickness | 8.75 to 175µm |

| 12 | Inner layer copper thickness | 17.5 to 175µm |

| 13 | Drilling hole diameter (mechanical drill) | 0.25 to 6.00mm |

| 14 | Finished hole diameter (mechanical drill) | 0.20 to 6.00mm |

| 15 | Hole diameter tolerance (mechanical drill) | 0.05mm |

| 16 | Hole position tolerance (mechanical drill) | 0.075mm |

| 17 | Laser drill hole size | 0.10mm |

| 18 | Board thickness and hole diameter ratio | 10:1 |

| 19 | Solder mask type | Green, Yellow, Black, Purple, Blue, White and Red |

| 20 | Minimum solder mask | Ø0.10mm |

| 21 | Minimum size of solder mask separation ring | 0.05mm |

| 22 | Solder mask oil plug hole diameter | 0.25 to 0.60mm |

| 23 | Impedance control tolerance | ±10% |

| 24 | Surface finish | Hot air level, ENIG, immersion silver, gold plating, immersion tin and gold finger |