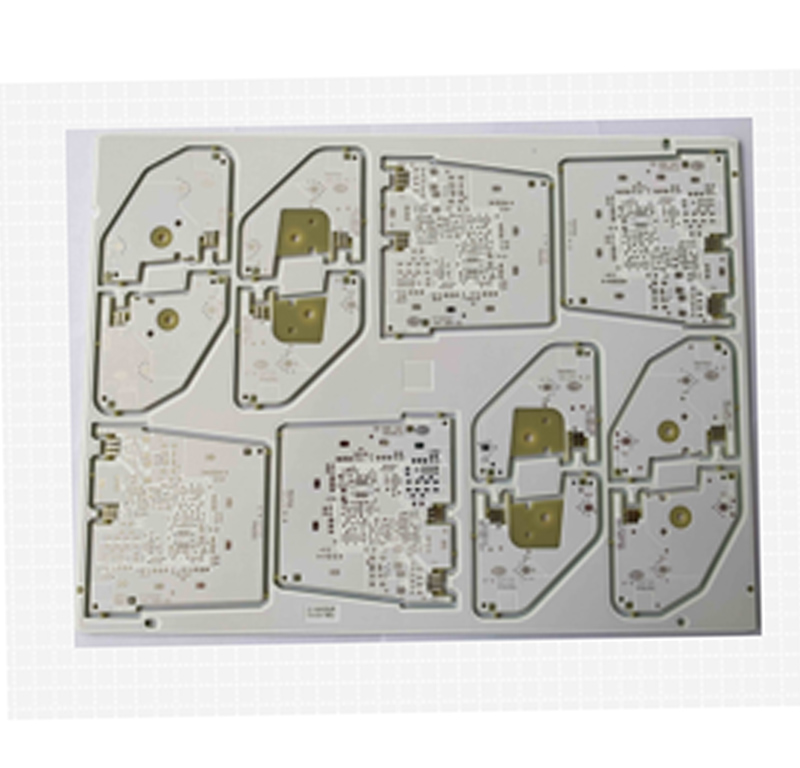

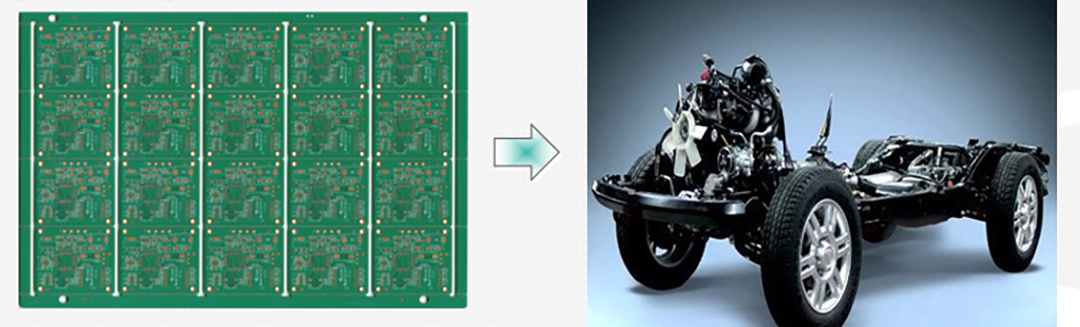

Automobile chassis brake system about the Cars Circuit Board

4-layers, board thickness 1.6mm

Min hole size 0.4mm, High TG

Immersion gold with impedance

Basic copper 2OZ

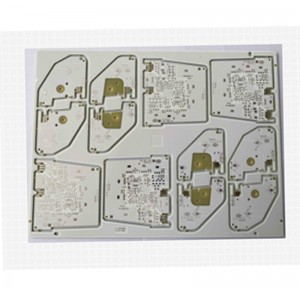

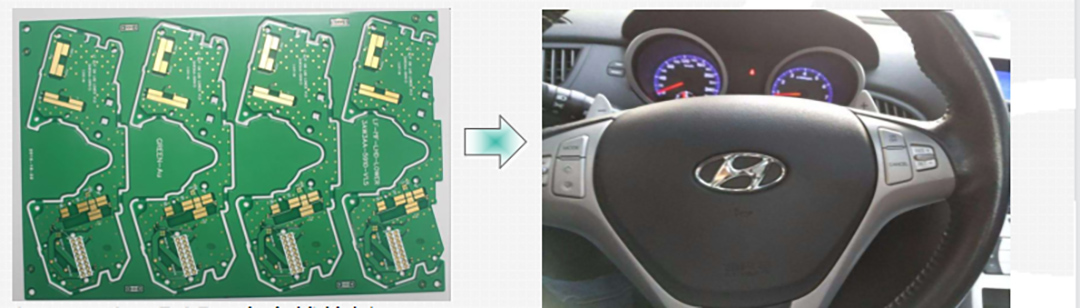

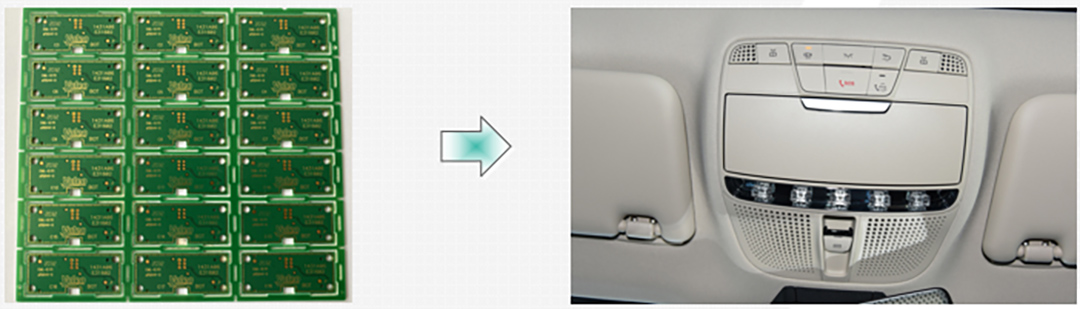

2-layers, board thickness1.6mm

Min hole size 0.4mm

Immersion Gold

Basic copper 2OZ

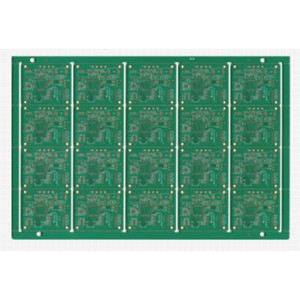

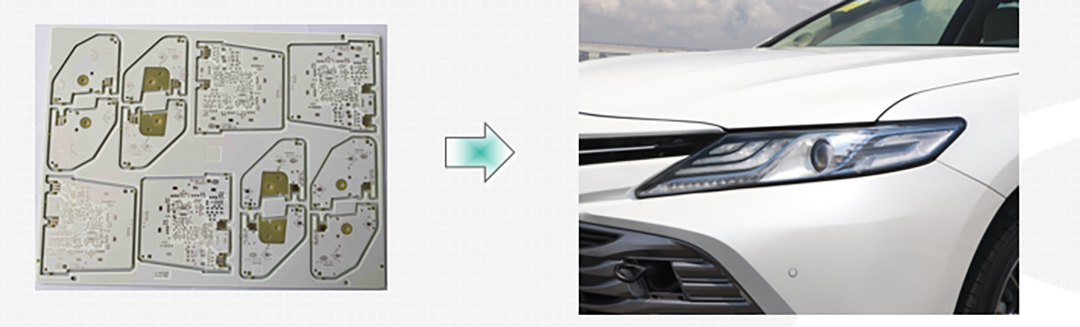

2-layers, board thickness1.6mm

Min hole size 0.8mm

LF HASL

Basic copper 1OZ

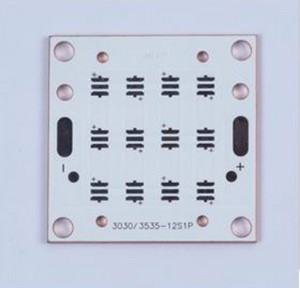

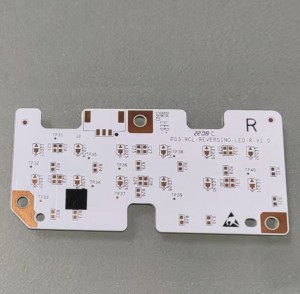

2-layers, board thickness1.6mm

Min hole size 0.4mm

Immersion Tin

Basic copper 1OZ

2-layers,board thickness1.6mm

Min hole size 0.3mm

Immersion Gold

Basic copper 1OZ

FR-4 PCB Technical Capability

| Item | Normal capacity | Limit capacity | Item | Normal capacity | Limit capacity |

| Layer No. | 2-16 | ≤20 | Max. copper thickness( Inner layer) | 4OZ | 5OZ |

| Core board thickness | 0.075-2.0mm | 0.05-3.0mm | Max. copper thickness( Outer layer) | 4OZ | 6OZ |

| min. PTH to copper | 165.1um | 152.4um | Min. space between SMD pads for S/M bridge | 203.2um | 177.8um |

| Board thickness(double sides) | 0.3-3.2mm | 0.3-4mm | Minimum legend width/height | 127um /762um | 101.6um /609.6um |

| Board thickness

(Multi-layer) |

0.6-3.2mm | 0.6-4mm | Outline dimension tolerance | ±101.6um | ±76.2um |

| Tolerance of board thickness(T≤0.8mm) | 0.1mm | 0.075mm | Bow & twist (T≤1mm) | ≤0.75% | ≤0.5% |

| Tolerance of board thickness

(T>0.8mm) |

±10% | ±5% | Bow & twist (T≤1mm) | ≤0.5% | ≤0.3% |

| Min. line width | 76.2um | 63.5um | Precision of hole to hole | ±0.05mm | / |

| Minimum line space | 68.58um | 63.5um | Impedance control range | ±10% | ±8% |

| Minimum hole diameter | 0.2mm | 0.15mm | Aspect ratio (0.2mm) | 10:1 | 12:1 |

| Tolerance of press fit hole diameter | 0.05mm | 0.05mm | Finished product size | 55-600mm | 10-620mm |

| profiling method | CNC、 V-CUT、 Punching or mold | ||||

| Surface treatment | EING、 OSP、 Immersion silver、 Selective OSP+ENIG | ||||

| Laminate type | FR-4.0, FR-4.1(Normal TG, middle TG, high TG), CEM-3, | ||||

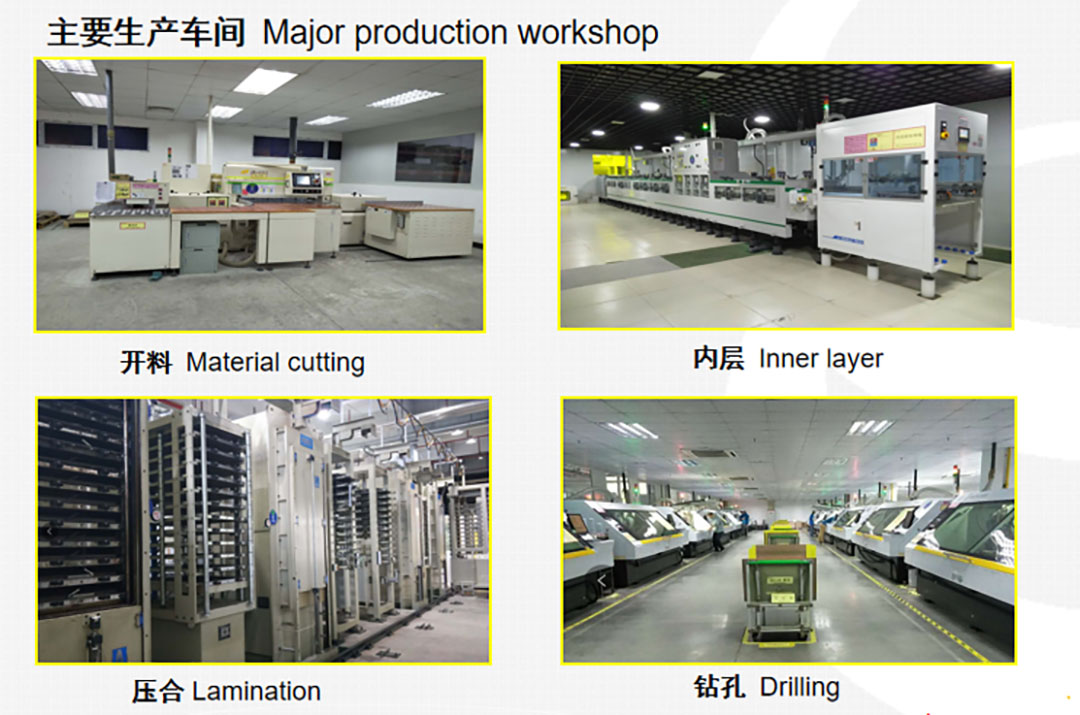

Factory Show

Introduction of FR4 materials

FR in FR4 represents a flame retardant, and the number 4 distinguishes the material from other materials in this class.FR4 is a glass fiber reinforced epoxy laminate that looks like a thin woven cloth sheet. The term FR4 also represents the grade used to make these laminates. The fiberglass structure provides structural stability for the material. The glass fiber is covered with flame retardant epoxy. This gives the material durability and strong mechanical properties. All of these features make the FR4 printed circuit board very popular among electronic contract manufacturers.