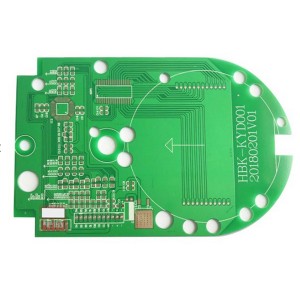

China Aluminum PCB, LED Bulb Light PCB, OEM/ODM MCPCB Manufacturer Printed Circuited Board

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for China Aluminum PCB, LED Bulb Light PCB, OEM/ODM MCPCB Manufacturer Printed Circuited Board, We sincerely hope to establish some satisfactory relationships with you in the near future. We will keep you informed of our progress and look forward to building steady business relations with you.

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for China Aluminum PCB, MCPCB, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

| Layer | 1 layer and 2 layer |

| Finished board thickness | 0.3~5mm |

| Min. line width/space | 4mil/4mil (0.1mm/0.1mm) |

| Min. Hole size | 12mil (0.3mm) |

| Max. Board size | 1500mm*8560mm (59in*22in) |

| Hole position tolerance | +/-0.076mm |

| Copper foil thickness | 35um~240um (1OZ~7OZ) |

| Remain thickness tolerance after V-CUT | +/-0.1mm |

| Surface Finished | Lead free HASL, immersion gold (ENIG), immersion silver, OSP, etc. |

| Base Material | Aluminum core, Copper Core, Iron Core, *SinkPAD Tech |

| Production capability | 30,000 s.q.m/month |

| Profile tolerance: routing outline tolerance | +/-0.13mm; punching outline tolerance: +/-0.1mm |

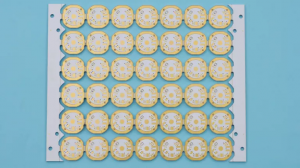

| Application of MCPCB | |

| LED lights | High-current LED, Spotlight, high-current PCB |

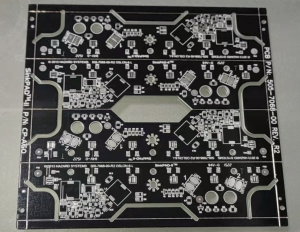

| Industrial power equipment | High-power transistors, transistor arrays, push-pull or totem pole output circuit (to tem pole), solid-state relay, pulse motor driver, the engine Computing amplifiers (Operational amplifier for serro-motor), pole-changing device (Inverter) |

| Cars | firing implement, power regulator, exchange converters, power controllers, variable optical system |

| Power | voltage regulator series, switching regulator, DC-DC converters |

| Audio | input – output amplifier, balanced amplifier, pre-shield amplifier, audio amplifier, power amplifier |

| OA | Printer driver, large electronic display substrate, thermal print head |

| Audio | input – output amplifier, balanced amplifier, pre-shield amplifier, audio amplifier, power amplifier |

| Others | Semiconductor thermal insulation board, IC arrays, resistor arrays, Ics carrier chip, heat sink, solar cell substrates, semiconductor refrigeration device |

We make efforts to meet excellence and perfection. Accelerating our steps to stand out the rank of international top-tier and high-tech enterprises for Aluminum PCB, LED & Bulb Light PCB, OEM/ODM MCPCB manufacturing. We sincerely hope to establish an invaluable relationship with you in nearly future. We will keep you informed of the production progress and expect to build steady business relations with you.

Here are our philosophies: good quality, outstanding service, keep improving. We are looking forward to more oversea friends joining our family for mutual development!