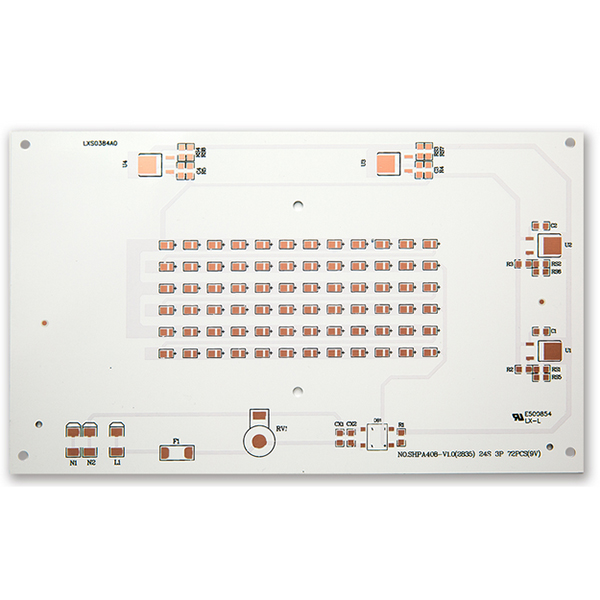

Low MOQ for Quick Turn Prototype - Best quality high power aluminum LED round LED PCB 220V, MCPCB , PCB board , 94VO PCB – Welldone

Low MOQ for Quick Turn Prototype - Best quality high power aluminum LED round LED PCB 220V, MCPCB , PCB board , 94VO PCB – Welldone Detail:

Product Details

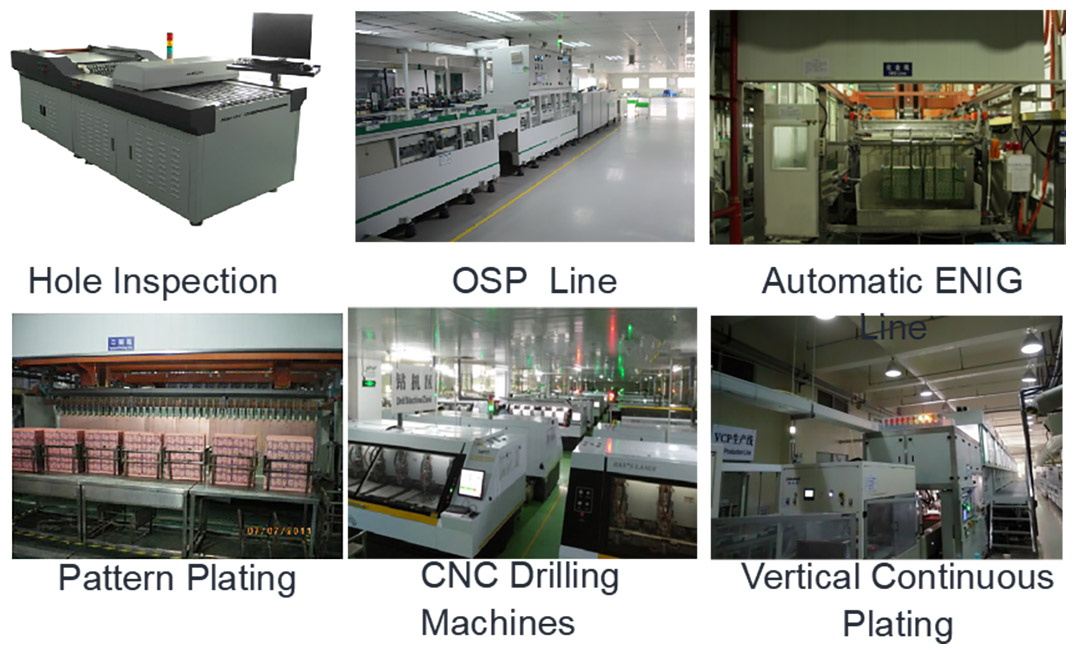

Production capability

| No | Item | Specifications |

| 1 | Min.Track Width | 0.2mm(8mils) |

| 2 | Min.Track gap | 0.2mm(8mils) |

| 3 | Min.SMD pad pitch | 0.2mm(8mils) |

| 4 | Product Type | AL Clad PCB 1layer~2layer |

| 5 | Maximum Panel Size | 20”*24”(1170*600mm) |

| 6 | Copper thickness | 0.5oz ~ 4oz |

| 7 | Dielectric Thickness (To Substrate) | 0.05mm-2mm |

| 8 | Substrate Core Thickness | 0.4mm-3.2mm |

| 9 | Finished Board Thickness | 0.4mm-4.0mm |

| 10 | Thickness Tolerance | +/-10% |

| 11 | Min.Finish hole size | 0.25mm |

| 12 | Soldermask color | Write, Black, Others Available |

| 13 | Reference Standard | IPC-A-600G Class 2 |

| 14 | Special Holes | Spot facing, Cup holes |

| 15 | Surface Finishing | HASL, HASL Leadfree, Immersion gold, Flash gold, OSP |

| 16 | Max.working voltage | 2.5KVDC(0.075mm Dielectric), 3.75KVDC(0.15mm Dielectric) |

| 17 | Data Input | Gerbers, AutoCad, Cam350, PROTEL 99SE, PROTEL DXP, POWER PCB, ODB+.(TGZ) |

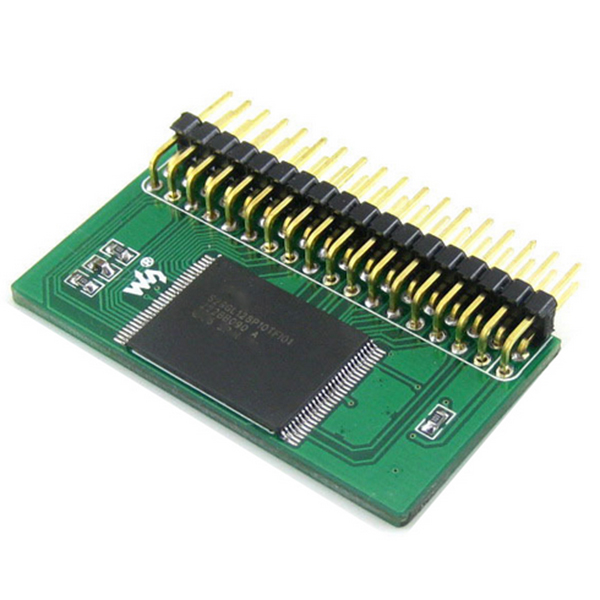

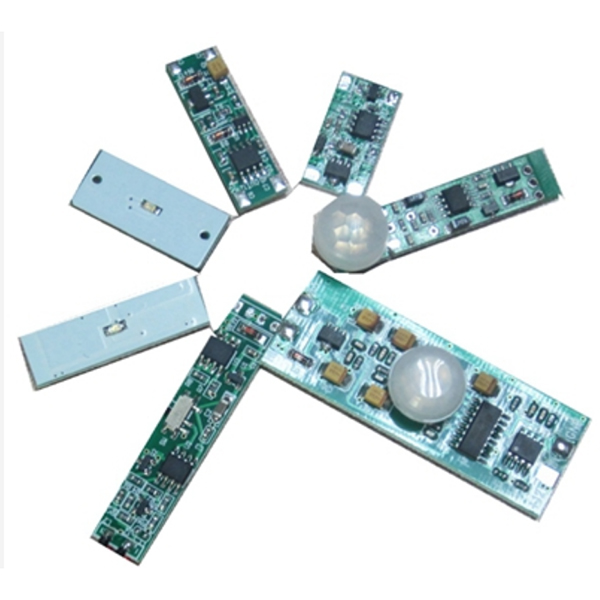

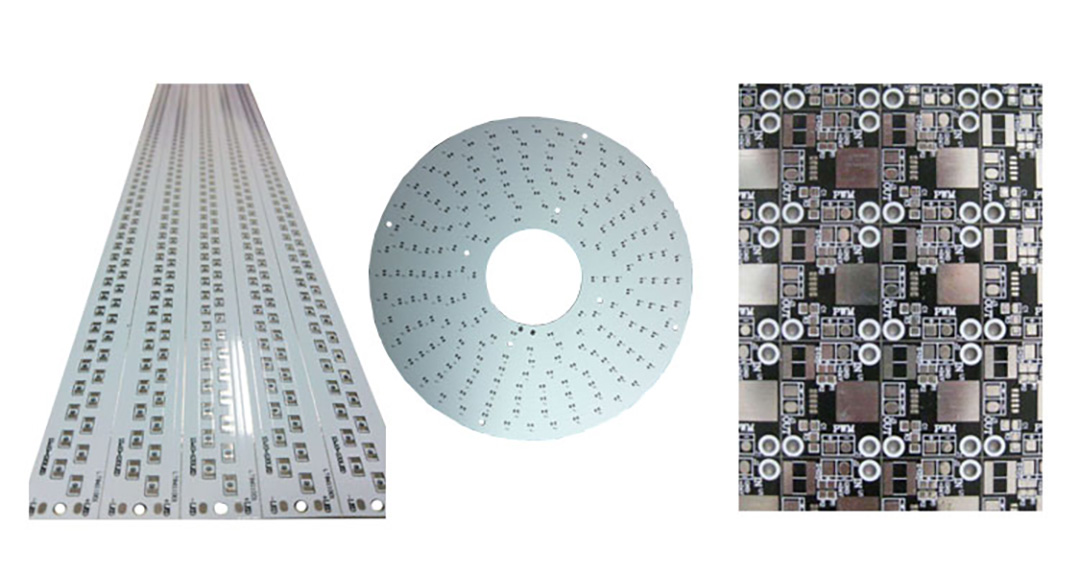

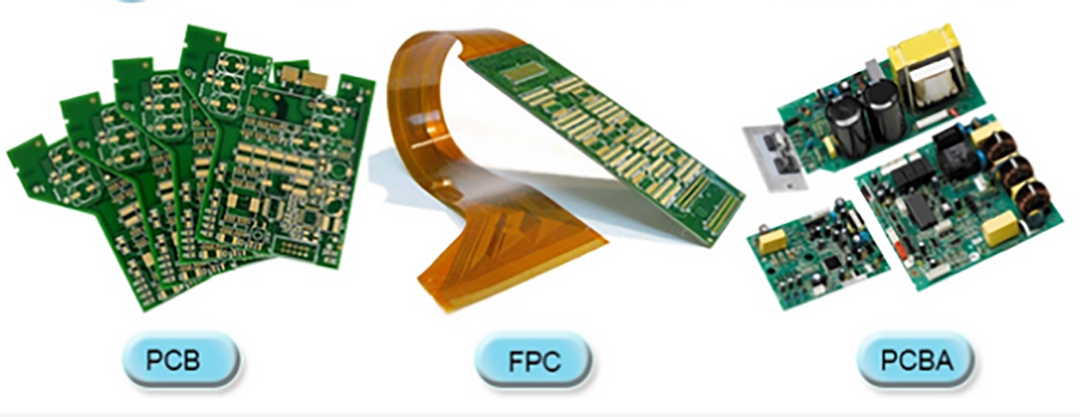

Related Products

Aluminium PCB

| 1. Aluminium PCB Circuit Layer The circuit layer (commonly used electrolytic copper foil) is etched to form the printed circuit, Compared to FR4 material, Aluminium PCB can bear higher electric current when same thick circuit layer and same trace width.2. Aluminium PCB Insulating Layer /Dielectic Layer The insulating layer is the core technology of the Aluminium PCB, which mainly serves as the function of adhesion, insulation and heat conduction. The better the thermal conductivity of insulation is, the quicker the components spread the heat when they work, which can realize the purpose like improving power loading of the modules,reducing volume, extending life span and increase the output power. WELLDONE has rich experience in manufacturing aluminium PCB with high thermal conductivity. 3. Aluminium PCB Metal Base Layer |

Company Information

Product detail pictures:

Related Product Guide:

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for Low MOQ for Quick Turn Prototype - Best quality high power aluminum LED round LED PCB 220V, MCPCB , PCB board , 94VO PCB – Welldone , The product will supply to all over the world, such as: Libya, Romania, Ghana, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

Write your message here and send it to us