-

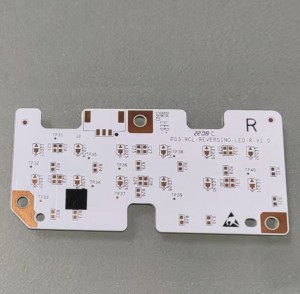

Automobile Reversing Light PCB Manufacturing for well-known brand in China.

These PCBs have revolutionized the way we drive and use our vehicles, from engine controls and airbag sensors to anti-lock brake management and even GPS support, and lighting parts of course. Almost every modern convenience in the car in your driveway or the fleet in your business’ yard relies on automotive PCBs.

-

Thermal management Printed Circuit Board (PCB)-SinkPAD TM

SinkPAD is a thermal management Printed Circuit Board (PCB) technology that makes it possible to conduct heat out of a LED and into the atmosphere faster and more efficiently than a conventional MCPCB. SinkPAD provides superior thermal performance for medium to high power LEDs.

-

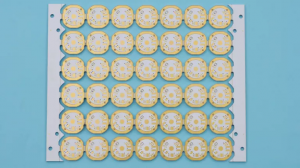

1W-3W-5W Aluminum PCB for Light bulb

The Aluminium PCB, also known as Aluminium Clad or Thermally Conductive PCB, is a special type of PCB that consists of thin thermally conductive and electrically insulating dielectric material.

Normally plastic or fiber glass substrate is used in the making of regular PCB, however, in the case of Aluminium PCB, the metal substrate is used; the reason it is also referred as metal base PCB.

Cost-effectiveness and high thermal conductivity are what make these boards stand out from the series of other circuit boards.

-

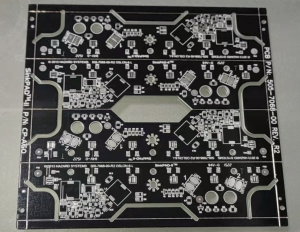

Custom Metal Core PCB for multiple applications

A Metal Core Printed Circuit Board (MCPCB), also known as a thermal PCB or metal backed PCB, is a type of PCB that has a metal material as its base for the heat spreader portion of the board. The thick metal (almost always aluminum or copper) is covering 1 side of the PCB. Metal core can be in reference to the metal, being either in the middle somewhere or on the back of the board. The purpose of the core of an MCPCB is to redirect heat away from critical board components and to less crucial areas such as the metal heatsink backing or metallic core. Base metals in the MCPCB are used as an alternative to FR4 or CEM3 boards.

-

Low-cost Aluminum core laminated copper foil SinkPAD PCB

What is the Thermoelectric Separation Substrate?The circuit layers and the thermal pad on the substrate are separated, and the thermal base of thermal components directly contact the heat-conducting medium to achieve the optimal thermal conductive (zero thermal resistance) effect. The material of the substrate is generally a metal (Copper) substrate. -

Direct thermal path MCPCB and Sink-pad MCPCB, Copper Core PCB, Copper PCB

Product Details Base Material:Alu/ copper Copper Thickness:0.5/1/2/3/4 OZ Board Thickness:0.6-5mm Min. Hole Diameter:T/2mm Min. Line Width:0.15mm Min. Line Spacing:0.15mm Surface Finishing:HASL,Immersion gold,Flash gold, plated silver, OSP Item name:MCPCB LED PCB Printed circuit board,Aluminum PCB,copper core PCB V-cut Angle:30°,45°,60° Shape tolerance:+/-0.1mm Hole DIA tolerance:+/-0.1mm Thermal Conductivity:0.8-3 W/M.K E-test voltage:50-250V Peel-off strength:2.2N/mm Warp or twist:</=0.5...